Ingredients Insight: What is the history of the Mars Chocolate R&D facility?

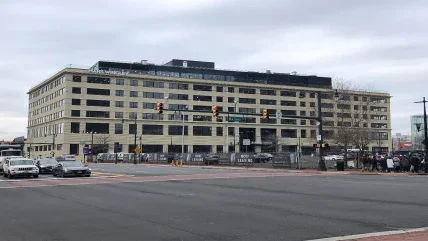

Geoff Bryant: Our new chocolate R&D facility officially opened last September in a ceremony attended by the Minister for Business and Enterprise, Michael Fallon. The £6-million investment has reinforced Mars Chocolate’s commitment to British manufacturing and to its birthplace in Slough, which is where the first Mars bar was manufactured 80 years ago.

The world-class centre is one of Mars Chocolate’s global R&D hubs and is home to more than 100 R&D associates, all of whom are working on exciting projects to fuel our chocolate innovation pipeline. The factory in Slough produces more than 2.5 million Mars bars every day, thanks to the skills of more than 1,000 people employed in our UK head office and factory.

How has business been since opening last year?

We have had a busy and exciting first year, which is testament to our commitment to innovation and ongoing focus on exciting consumers with new products. The facility has been central to the development of new releases including our biggest innovation in a decade, the Maltesers Teasers – our best-loved Maltesers in a bar and block format.

We also had the honour of hosting Her Majesty The Queen in our new R&D centre in April. The Queen met some of our outstanding R&D team and was presented with a scale model of the coronation carriage, made out of chocolate. Two of our chocolatiers, both former chefs, created the model.

Why Slough as a location?

Our investment in the facility was designed to bring R&D to the very heart of our business, which is why it’s located on the same site as our factory and our head office in Slough.

Slough has been the home of Mars Chocolate in the UK for over 80 years – since the factory first opened its doors in 1932. We’re extremely proud of our heritage there and that’s one reason why we do so much work with the local community; for example, we’re involved in the Slough Aspire programme, which offers a range of training programmes and career advice services for unemployed people in the area.

How is the Mars centre set up and what are its areas of expertise?

There are more than 100 Mars associates working within the R&D facility. The team is made up of several key functions and areas of expertise, which work together to develop the innovative confectionery products you see today. Focus areas include a dedicated design team, which ensures our brands delight consumers in and out of their packaging; science and technology teams, who work on delivering breakthrough future technologies for new and existing products, and product development and quality teams, who specify and value-engineer our products and ensure they can be delivered in our factories with high levels of quality

for a great consumer experience.

What are the unique features and equipment at the centre?

The Slough facility is home to state-of-the-art kitchens and laboratories, as well as a pilot production line where new product developments are test-manufactured. This allows us to create unique new products that are desirable to consumers and feasible to make. For example, to manufacture new Maltesers Teasers we made an additional £4-million investment in the manufacturing facilities, which allowed us to produce the miniature honeycomb pips that deliver the unique melt-in-the-mouth, yet crispy attribute of the Maltesers Teasers bars.

Can you discuss the findings coming out of the R&D centre?

It is important for businesses to think about how a focus on innovation can create value in a sustainable way, while ensuring innovative behaviours become more embedded in the culture. With a strategic pipeline of new product and packaging development, we continue to grow our brands for the long term to meet the demands of consumers and customers.

What products are manufactured at the Slough factory?

The Mars Chocolate factory in Slough manufactures many of the nation’s favourite treats, including Mars bars, Snickers, Galaxy and Maltesers.

How do you see the business moving forward over the next five years and beyond?

New talent is the future of the industry, and we believe that this is the best way to continue to drive the business and confectionery industry forward. We invest a lot of time and effort in nurturing and developing talented associates within the company. With the right people and skills, the future at Mars Chocolate looks set to continue to drive innovation and quality, and set a benchmark for the industry.

What are the key market opportunities for Mars?

By understanding the needs of our consumers and customers, we believe that we can delight them and grow our brands through product and packaging innovation. While chocolate continues to grow, innovation is crucial if the category is going to thrive in a tough economy.

Whether customers are looking for an on-the-go sweet treat, or a bite-size pouch to share with friends, shoppers are keen to try new products from the brands they trust, and we are constantly looking at ways to excite consumers with new products and formats. This year we have taken two of our best-loved products, Mars and Twix, and taken them into a new format with Mars Mix and Twix Mix.

Looking ahead, what are the sector’s main challenges for 2014?

One thing that I don’t think will change will be peoples’ desire for innovative products, and we have some great concepts in the pipeline, but we also need to ensure that our core brands remain iconic and relevant through continuous quality improvement, and development of new formats and great packaging.

What are the factors that make a good R&D centre?

At Mars, we have five guiding principles that are embedded in everything we do: quality, responsibility, mutuality, efficiency and freedom. These are not important only as a way of ensuring best practice across our entire supply chain, but also in creating a great working environment that gives all our associates the opportunity to do their best and have a real effect on the end product of our business. This is what makes Mars Chocolate a great place to work, as well as one of the world’s most successful chocolate manufacturers.

Thinking innovation, are there areas where Mars could improve?

The quality of our associates is the key to remaining innovative. We work very hard to nurture the very best talent we already have, as well as looking for opportunities for the brightest and best scientists, designers and engineers to join us. Having a diverse range of talent and experiences within our teams drives innovation in our chocolate business.

Can you provide a case study detailing a product or innovation that has gone through the laboratory, from start to finish?

Maltesers Teasers has been our biggest innovation for a decade and we’re proud that it was born at the Slough R&D facility here in the UK.

Originally described as ‘energy balls’, the first bag of Maltesers was sold over 75 years ago and the brand has become one of the best-loved confectionery products in the UK, particularly as a sharing product and a seasonal favourite.

Maltesers Teasers was the first permanent line to be launched from the new R&D facility and the concept was based on insightful feedback directly from consumers. Once the final prototype had been developed in the lab kitchens, it was scaled up in our pilot plant and then the final product was produced on a mass scale at the factory in Slough. Maltesers Teasers were launched on 5 March 2013 and distributed to retailers across the country, ranking number one in the top ten chocolate singles just 12 weeks after the launch.